Pulwell Fiberglass (GFRP) Conduit

--Functional, Cost-Effective Rigid Cable Conduit Systems

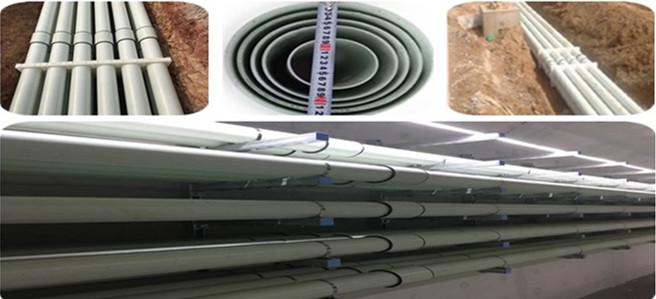

The Infrastructure Industry largely relies on conduit. Pulwell’s lightweight but tough, fiberglass conduit systems are often more cost effective and durable than traditional PVC, MPP,PE or steel counterparts. Pulwell fiberglass Conduit system consists of FRP conduit tubes, couplings, bushings and spacers. It is designed to provide power, telecommunications and transit utilities as well as commercial and industrial markets with a reliable, easily installed carrier for below ground and above ground applications.

Why Fiberglass (GFRP) conduit

Because of its superiority to other materials in practically every area, fiberglass conduit is increasingly seen as the best option for a myriad of projects. Fiberglass reinforced conduit products offer numerous advantages over alternatives in the areas of safety, longevity, strength, flexibility, durability, and weight.

Main advantages of fiberglass conduit include:

◎High impact and crush resistance

◎Nonmetallic. Will not rust or corrode

◎Nonmetallic. Will not rust or corrode

◎Non-conductive, assuring a safe system

◎High strength and high stiffness

◎Lightweight

◎Corrosion protection

◎Low Thermal expansion rate

◎Low coefficient of friction, no burn-through

◎Wide Temperature Tolerance (-60℃ to 200℃)

◎Fire resistant and non-toxic

◎High stiffness

◎No maintenance

◎Ability to retain its shape after impact or compression

Why Pulwell Fiberglass (GFRP) Conduit System

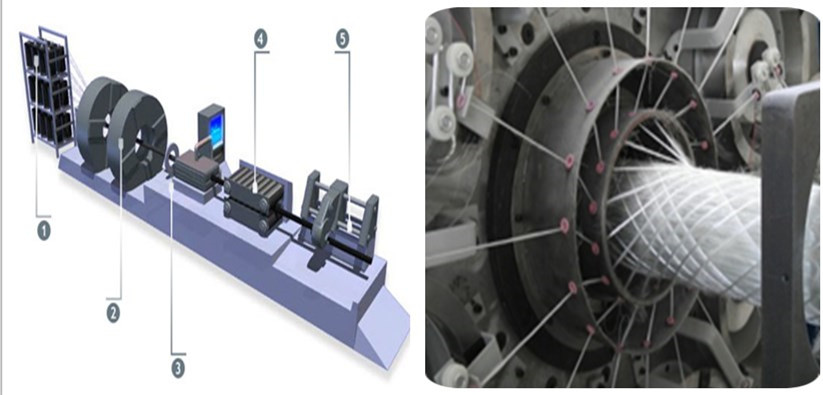

How we make the fiberglass conduit tube

Different from the traditional FRP winding process, Pulwell produces high-performance fiberglass conduit products using continuous manufacturing pull-winding process to reach consistently high quality product. Thanks to our patented technology with combination of pultrusion and winding technology, our pull-winding process is capable of designing different reinforcements such as unidirectional fibers, continuous strand mat as well as helical winding of fibers from a few degrees up to 90 degrees and results in a steady output of fiberglass conduit tube in constant wall thickness. Our process is highly flexible and easily adaptable to efficiently create products of different, custom specifications. This allows us to deliver competitively priced solutions for our customers that can be turned around without overly extended lead times.

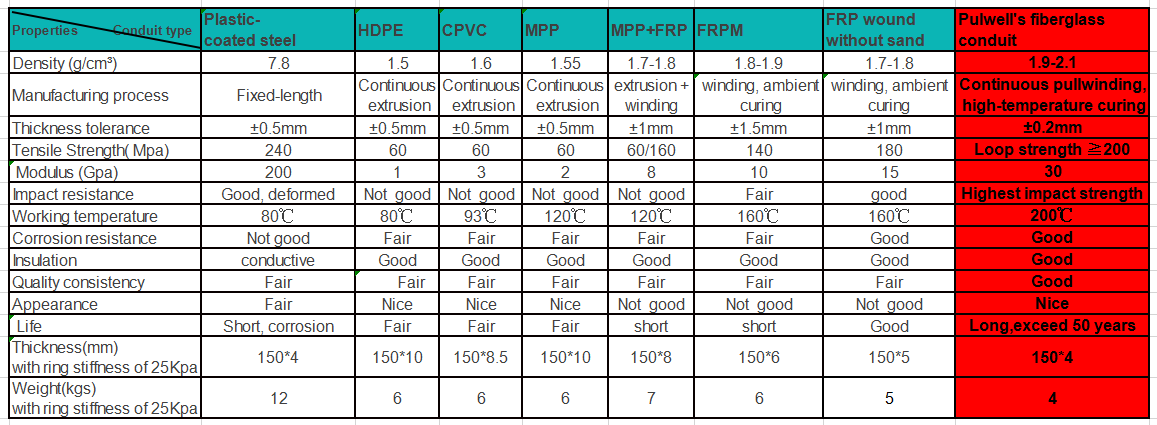

Properties Comparison of Pulwell Fiberglass Conduit with Traditional Conduits

Pulwell fiberglass Conduit system is better, safer, more economical, and longer-lasting than all previous traditional conduits. Our fiberglass conduit not only performs as well or better than the other "traditional" products, but it also offers extended benefits that range from significant overall cost savings to reduced environmental impacts.

Benefits using Pulwell Fiberglass Conduit System

◎ Longest life cycle of any conduit system:environmentally resistant, non-conductive and non-corrosive! Simply outlasts and outperforms other conduit systems!

◎ Lowest installed cost:Fewer supports and fittings combined with ease of installation significantly reduce labor and material costs compared to other conduit systems.

◎Highest strength to weight ratio of any conduit system. Retains shape after impact and will not deform.

◎Safest system to install: the light weight of fiberglass compared with PVC and steel results in increased job productivity, fewer injuries and reduced worker fatigue.

◎ Wide operating temperature range:-60°C to 200°C, whereas PVC is only rated to 90°C. Can be installed in hot and cold environments without loss of mechanical properties. Does not sag or become brittle.

◎ No cable fusion under fault conditions.Cables will not adhere to the conduit wall.

◎Non-Conductivity: Fiberglass conduit is an excellent insulating material.

◎ Low coefficient of friction:Pull cables further than PVC. Allows for fewer manholes, lower material costs, and lower labor costs.

◎ Easy-fit assembly:Conduit and fittings are easily to cut and join in the field.Straight sleeve coupling with quick push-fit seal system.

◎Low coefficient of thermal expansion: less than PVC and comparable to steel,results in fewer expansion joints and support hardware.

◎Rodent-proof/Rot proof.

◎Low toxicity: fiberglass conduit does not release harmful toxins such as chlorine and bromine when burned.

◎Cost-effective-- All Reliable Savings

• Extremely lightweight to work with and lower handling costs

• Easy to cut, Faster to install, and lowest installation costs

• Easy connections--No adhesive or threading and quick push-fit seall assembly

• Affordable material cost

• Expanded support spacing distances

• Best overall value and returns for investment with:

Lower maintenance

Better, more consistent performance which reduces emergency repairs

Available Sizes and Grades of Pulwell Fiberglass Conduit

|

Inner Diameter ( ID,mm) |

Wall thickness (mm) in different grades of ring stiffness |

||

|

25Kpa |

50Kpa |

100Kpa |

|

|

100 |

3 |

4.5 |

7 |

|

125 |

3.5 |

5 |

7.5 |

|

150 |

4 |

5.5 |

8 |

|

175 |

4.5 |

6 |

8.5 |

|

200 |

5 |

6.5 |

9 |

|

225 |

5.5 |

7 |

9.5 |

|

250 |

7 |

8.5 |

11 |

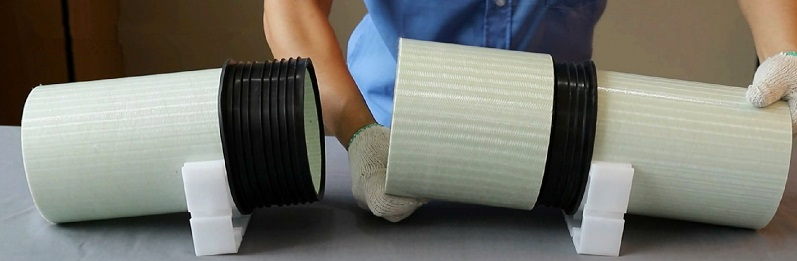

Available Accessories

Fiberglass sleeve couplings

Duct Spacers

Push-fit seal

Applications of Pulwell Fiberglass Conduit System

The benefits offered by Pulwell Fiberglass conduit system, including corrosion resistance, cost-effectiveness, lighter weight, and expanded support spacing distances contribute to growing use across the board and savings, industry by industry, for power, telecommunications and transit utilities as well as commercial and industrial markets.

Main Applications:

◎Transportation/Infrastructure

◎Port Authority/Coastal Environments

◎Commercial projects such as Airports, Stadiums,Trenchless,Universities

◎Industrial projects such as Wastewater Treatment,Chemical Plants,Food Processing,Pulp and Paper Plants

◎Utilities/Data Centers

Pulwell fiberglass conduit system shall be the best way to go, if you want your conduit project to be costeffective and to last. Contact us for more details.

No.20 Lianhong Road, Torch High-Tech Industrial Zone, Zhongshan City, Guangdong 528437, PRC

Copyright © 2025 Pulwell Composites Co.,Ltd. All rights Reserved

Tel:+86-760-86133399, Fax:+86-760-86133398