Pulwell manufactures Basalt fiber rebars by combining the pultrusion process and an in-line winding & coating process for the outside sand surface. The BFRP composite rebar is made from high strength Basalt fibers along with an extremely durable Epoxy resin. The Basalt fibers impart strength to the rebar while the Epoxy resin imparts excellent corrosion resistance properties in harsh chemical and alkaline environments. BFRP rebar in permanent application can significantly improve the longevity of civil engineering structures where corrosion is a major factor.

----A SUPERIOR ALTERNATIVE TO CONVENTIONAL STEEL REBAR

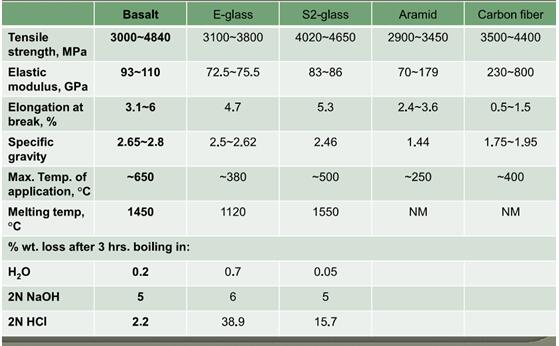

Basalt fiber comparing with the other fibers

Unique properties of Basalt fiber comparing with E-glass fiber

1.Better acid and alkali resistance

2.Higher tensile strength and higher Modulus

3.Naturally resistant to ultraviolet (UV)

4.Higher temperature resistant

Pulwell’s BFRP Rebar is a sort of electrical insulator, which has the nonmagnetic, high acid-resistance, alkali- resistance. BFRP has the high permissibility for the moisture concentration of the cement mortar & the permeability, diffusion of the carbon dioxide. Theses can prevent the concrete construction from eroding to enhance its endurance.

resistance. BFRP has the high permissibility for the moisture concentration of the cement mortar & the permeability, diffusion of the carbon dioxide. Theses can prevent the concrete construction from eroding to enhance its endurance.

Technical advantages of BFRP Rebars

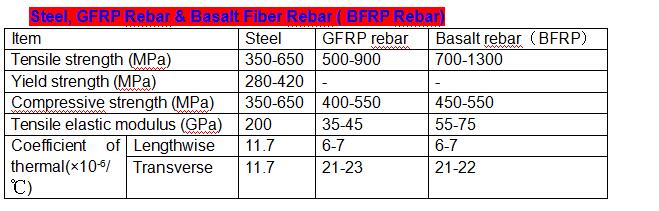

Basalt fiber Rebars ( BFRP Rebars) offer significant advantages over steel rebar in a variety of permanent applications.

1.Much higher tensile strength than steel or fiberglass rebar of the same diameter.

2.Strength + Zero rusting allows for thinner, lighter panels and decks. Since BFRP rebar does not rust or absorb water, the need for spacing between the rebar and the surface of the concrete is reduced. This allows for thinner projects and more flexible designs using less expensive & heavy concrete.

3. Much lighter than steel rebar. Many jobs will not require hoists or forklifts to handle BFRP rebar supplies. The result is much less fatigue for installation workers as compared to steel. A reduction in injuries and medical expenses can also be expected. Its light weight allows for much faster installation and a better overall job.

4.No permanent deformation when bent. Diameters of up to 12mm can be coiled for shipment and used in long runs such as bridge decks and sea wall caps. The Rebar will naturally straighten when unrolled.

4.No permanent deformation when bent. Diameters of up to 12mm can be coiled for shipment and used in long runs such as bridge decks and sea wall caps. The Rebar will naturally straighten when unrolled.

5.Exactly the same thermal coefficient of expansion as concrete.

6. BFRP rebar is naturally resistant to corrosion, rust, alkali, and acids. Chemically inert, basalt rebars are compatible with concretes having different Ph values. BFRP rebar has better alki-resistant property than GFRP rebar

7.Does not absorb and transfer moisture like glass fibers do. Exposed fibers will not create a path for water to penetrate and destroy concrete.

8.Does not conduct electricity.

9.Non magnetic, does not induce fields when exposed to RF energy, so it can be used in applications like MRI rooms and around RFID readers.

10. Easily cut to length in the field with common tools.

Applications

When BFRP rebars are used to reinforce concrete, basalt Rebar reinforcement is an advanced alternative to steel rebar. Ideal for:

When BFRP rebars are used to reinforce concrete, basalt Rebar reinforcement is an advanced alternative to steel rebar. Ideal for:

• Hydraulic Engineering, especially structures built in or close to seawater

• Road Construction, especially high-speed roadways, bridges, runways, concrete barriers and reinforced concrete exposed to deicing salts

• Applications Subjected to Other Highly Corrosive Conditions,·such as channel pipes, pools, wells, ports, dry docks and etc

• Applications Subjected to Other Highly Corrosive Conditions,·such as channel pipes, pools, wells, ports, dry docks and etc

• Applications Requiring Low Electric Conductivity or Electro-magnetic Neutrality

• Walling Structures: such as Dome, architectural constructions, fences, columns, modeling with rebar reinforcement, concrete building and facing slabs

• Walling Structures: such as Dome, architectural constructions, fences, columns, modeling with rebar reinforcement, concrete building and facing slabs

• Restoration of ferroconcrete structures

BFRP rebars are also an alternative building and construction solution in regions prone to earthquake and seismic hazards.

Stirrups, Shapes , Bends and Continuous Rebars

Like GFRP rebars, bends in Pulwell BFRP Rebar are fabricated by shaping over a set of molds or mandrels prior to curing of the resin matrix. Field bends are not allowed. All bends must be made at the factory. Research has shown that bends typically maintain 40% of ultimate tensile strength through the radius.

Like GFRP rebars, bends in Pulwell BFRP Rebar are fabricated by shaping over a set of molds or mandrels prior to curing of the resin matrix. Field bends are not allowed. All bends must be made at the factory. Research has shown that bends typically maintain 40% of ultimate tensile strength through the radius.

It is recommended that you work with the factory in the early stages of design, as not all standard bends and shapes are readily available.

The narrowest inside stirrup width is 10". Bends are limited to shapes that continue in the same circular direction. Otherwise lap splices are required.

Continuous BFRP rebars with diameter below 12mm in specific lengths are available.

Field Handling and Placement Considerations

Unrolling BFRP rebar coils. Substantial kinetic energy is stored during the coiling process. Care must be exercised when uncoiling to prevent tangling and uncontrolled movement of ends. Coils are shipped with U  clamps to allow uncoiling from the inside of the coil for safety reasons.

clamps to allow uncoiling from the inside of the coil for safety reasons.

Cutting in the field. Cable cutters do work well on sizes 12mm and smaller, however frequent sharpening is required. When necessary, cutting of BFRP rebars should be done with a masonry or diamond blade, grinder or fine blade saw. A dust mask is suggested when cutting the bars .It is recommended that work gloves be worn when handling and placing BFRP rebars.

Sealing of cut ends is not necessary since any possible wicking will not ingress more than a

small amount into the end of a rebar.

BFRP rebar has a very low specific gravity and will tend to "float" in concrete during vibration. Care should be exercised to adequately secure BFRP in formwork using chairs, plastic coated wire ties or nylon zip ties

Rebars with hybrid fibers of basalt fiber & Glassfiber are also available.

No.20 Lianhong Road, Torch High-Tech Industrial Zone, Zhongshan City, Guangdong 528437, PRC

Copyright © 2025 Pulwell Composites Co.,Ltd. All rights Reserved

Tel:+86-760-86133399, Fax:+86-760-86133398