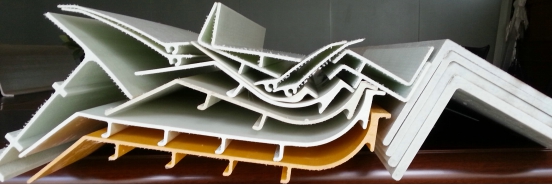

With more than 20 years of experience plus over 100 different pultruded profiles and custom shapes, Pulwell offers a unique blend of experience and design capabilities to provide engineered solutions.We can take your idea from concept to final product reality.

Some specific customer requirements may include, elevated temperatures, corrosive environments, UL rated non-conductive systems, high shear strength, high flexural modulus, stiffness and, of course, low cost. A custom pultrusion is a pultruded product customized in one or more of the following ways to meet a customers specific requirements:

UL rated non-conductive systems, high shear strength, high flexural modulus, stiffness and, of course, low cost. A custom pultrusion is a pultruded product customized in one or more of the following ways to meet a customers specific requirements:

Shape: Virtually any constant cross-section part can be pultruded.

Resin Matrix: Standard resin systems can be modified or special resins used to address such needs as elevated temperatures or special environments. Typical resins include polyesters, vinyl esters, epoxies, phenolics, urethanes and blend.

Reinforcements: Typical reinforcements are fiberglass or carbon fibers in multi-filament strands, mat, woven fabrics or stitched fabric. Other reinforcement types such as basalt fiber, aramid fiber and forms are possible.

Composite Design: The selection of the resin mix, the type and form of reinforcements, and the placement of reinforcements within the composite are all ways a composite design can be customized.

Custom pultrusions contrast with standard "off-the-shelf" pultruded products in which all of the above elements are pre-established.

Benefits of pultruded products include:

o High strength-to-weight ratios

o Corrosion resistance

o Heat resistance

o Dielectric properties

o Dimensional stability

o Weatherability

Benefits of custom pultrusions include:

o A specific design to meet your unique application needs

o Assistance from experienced engineers

o Optimized profiles for strength, durability & reliability

o Lower life-cycle cost

Whatever your design need for your specific application, we can deliver. To serve our customers more efficiently we operate a 24-hour per day, 7 day per week production schedule.

APPLICATIONS USED FOR CUSTOM PULTRUSIONS

Pulwell has manufactured custom pultrusions across many types of industries for the below applications.

o Fiberglass Struts

o Pipe Supports

o Electrical Supports

o Cable Tray

o Static Arrestors

o Busbar Insulators

o Cored Tubing / Handles

o Radomes

o Utility Line Markers

o Hog Pen Supports

o Telescoping Ham Radio Poles

o Armour Plate

o Refrigeration Components

o Highway Sound Barriers

o Cooling tower panels and frames

Contact Pulwell for more information

No.20 Lianhong Road, Torch High-Tech Industrial Zone, Zhongshan City, Guangdong 528437, PRC

Copyright © 2025 Pulwell Composites Co.,Ltd. All rights Reserved

Tel:+86-760-86133399, Fax:+86-760-86133398